0 items in quote

.jpg%3Fv%3D3&w=3840&q=75)

Worldwide export

Premium tested machines

Readily available

Trade in possible

2800+ machines in stock

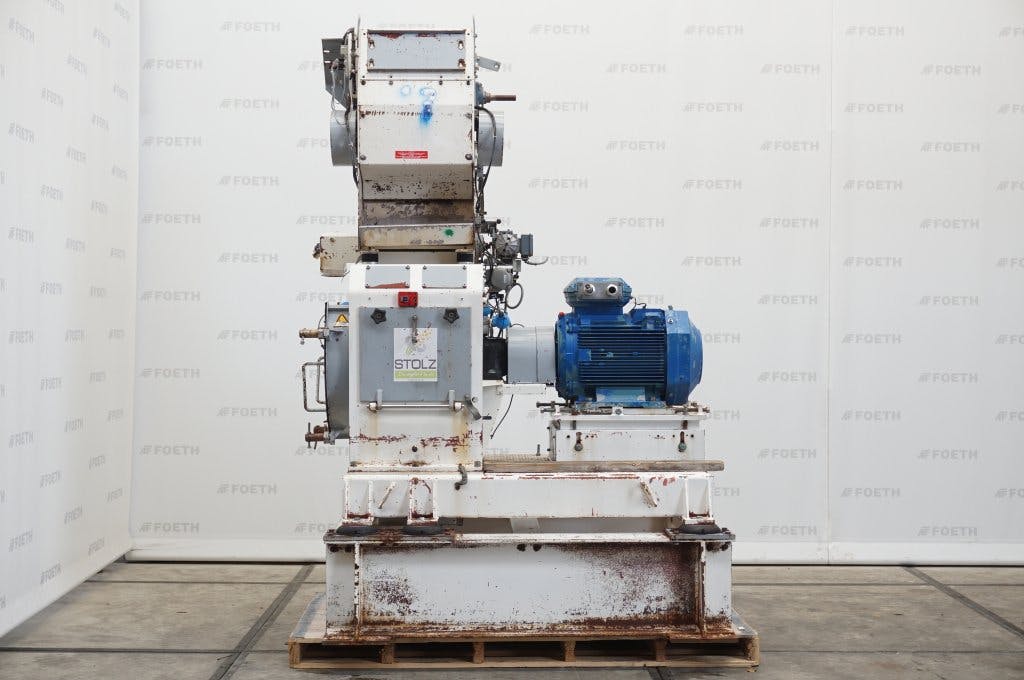

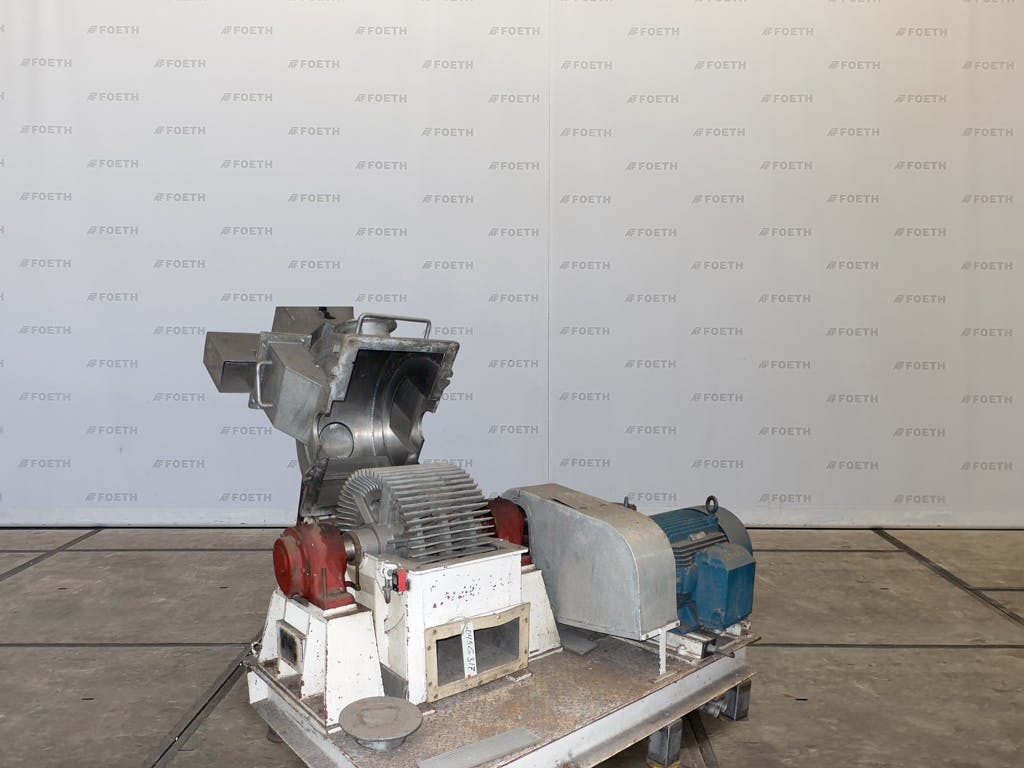

Hammer mills are high-precision equipment for crushing solid and hard granules, guaranteeing uniform grinding and a noiseless operation. Besides, they lead to minimal heat build-up, which is perfect for heat-sensitive materials. Hammer mills are ideal for pharmaceutical and food processing plants since they crush and reduce raw materials to suitable sizes. Foeth has new and second-hand options if you seek a hammer mill. You can choose high-quality mills from different brands in optimal operating conditions. Foeth’s hammer mills are ideal for various industries and can be adapted to specific types of products or manufacturing processes. You will also receive expert advice on picking the ideal mills for your agri-food or chemical manufacturing businesses.

Order a high-performing hammer mill from Foeth.

.jpg%3Fv%3D3&w=3840&q=75)

.jpg%3Fv%3D3&w=3840&q=75)

.JPG%3Fv%3D3&w=3840&q=75)

We only have machines from premium European manufacturers and mechanically test prior to shipment

Foeth has the largest stock in Europe and we update our inventory on a weekly base.

All our machines are available on our premises, ready to be tested and shipped to you!