0 items in quote

Worldwide export

Premium tested machines

Readily available

Trade in possible

2800+ machines in stock

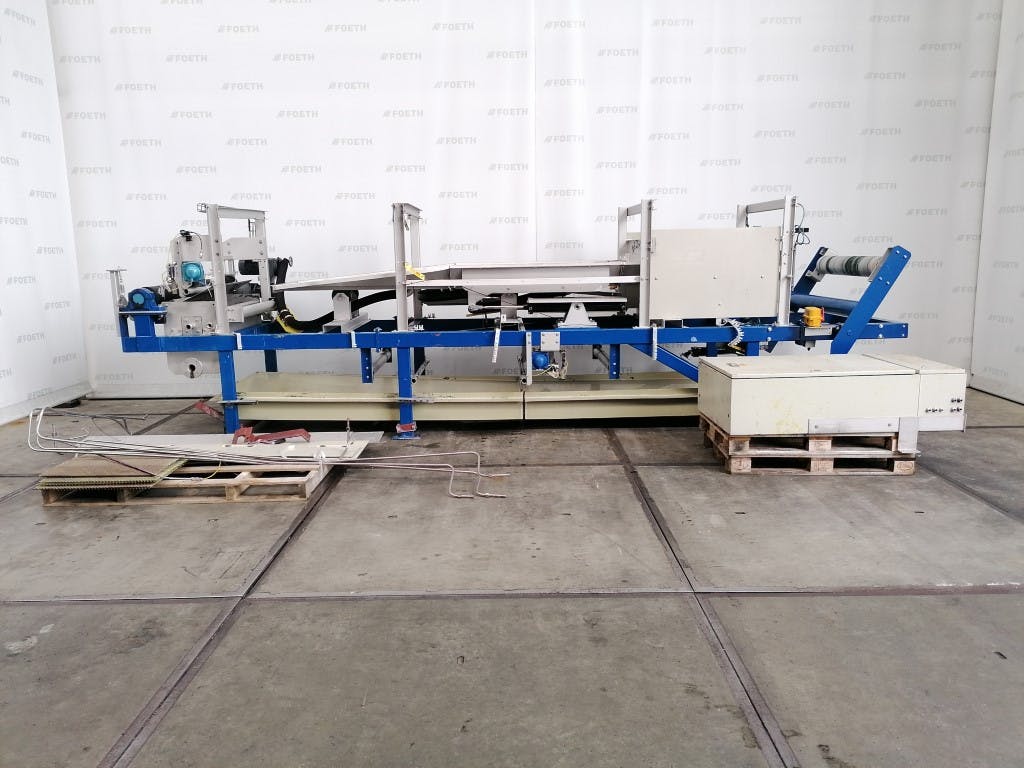

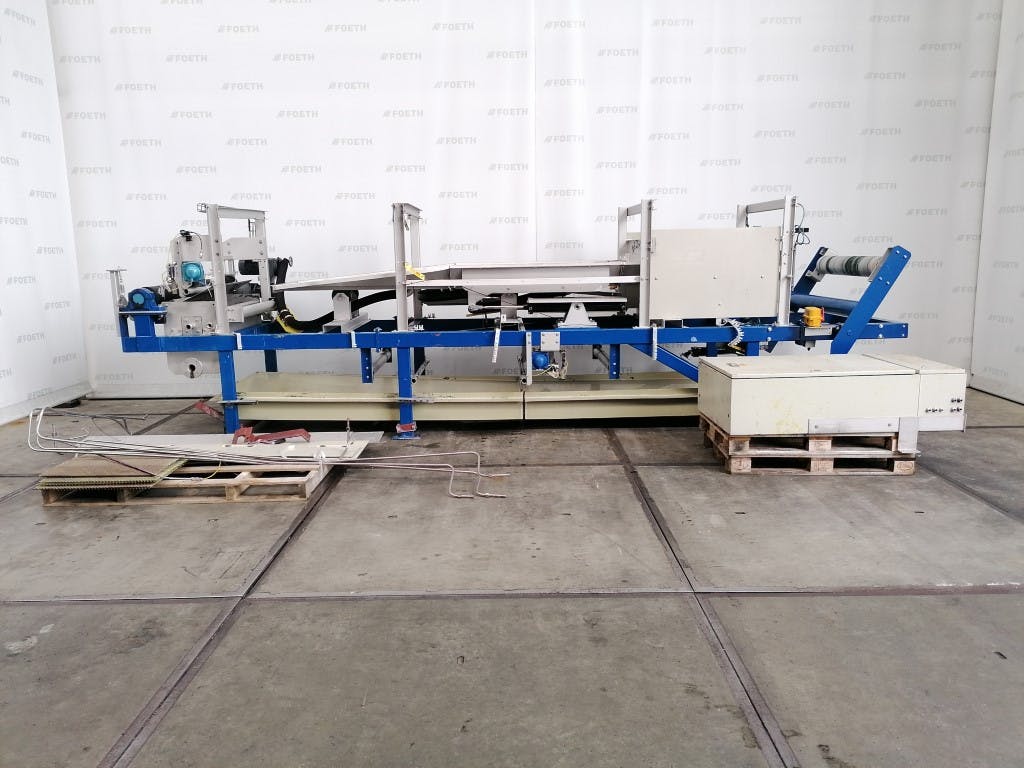

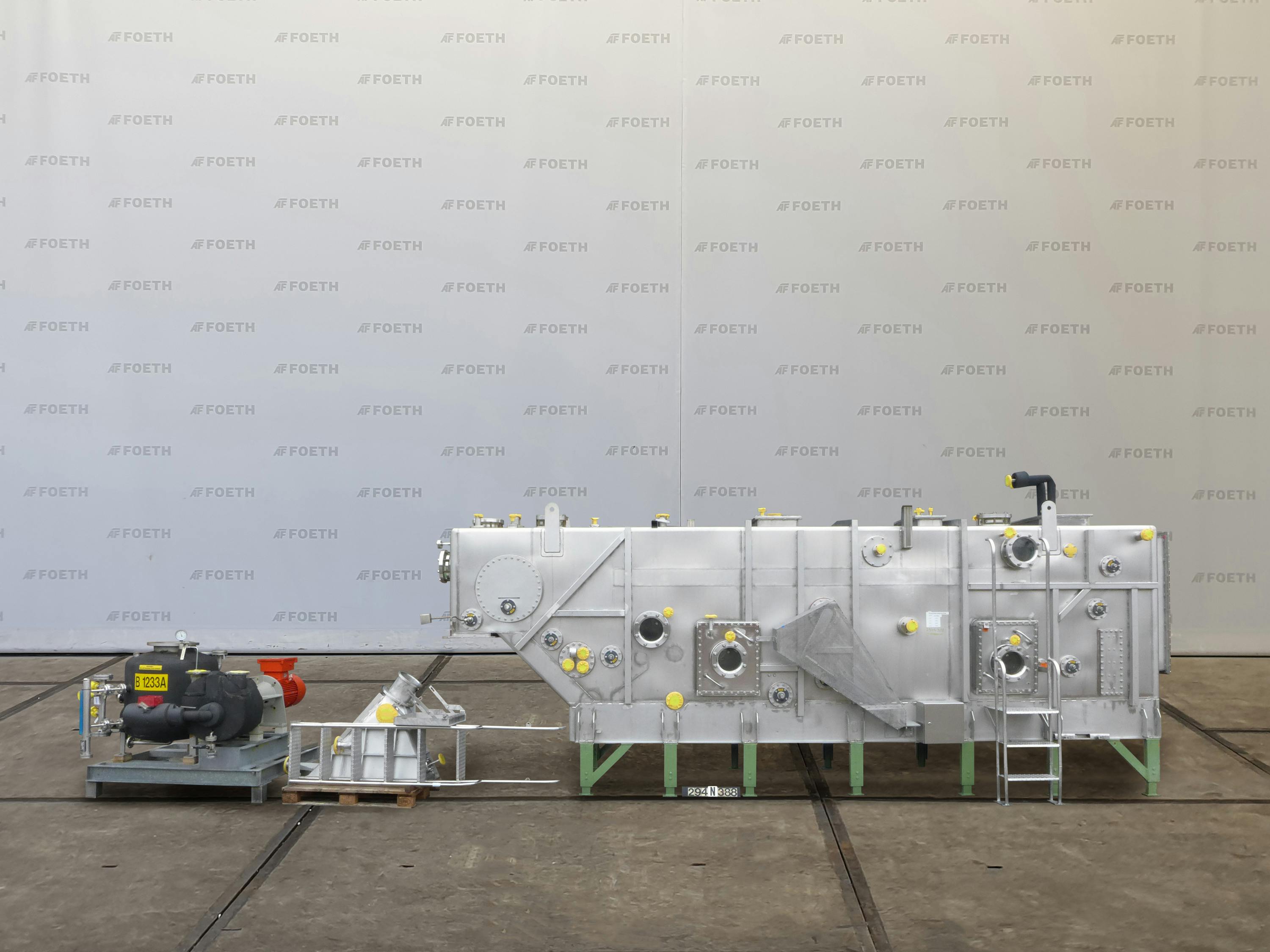

One of the most commonly used processes in industrial applications is the separation of solids and liquids using vacuum and a filter. At Foeth, we offer a wide variety of used vacuum band filters from recognized brands, such as Pannevis and BHS Sonthofen. Moreover, we have the largest inventory of second-hand process equipment in the best condition and ready for operation.

Check our current online stock of vacuum band filters or request a quote directly!

.JPG%3Fv%3D3&w=3840&q=75)

We only have machines from premium European manufacturers and mechanically test prior to shipment

Foeth has the largest stock in Europe and we update our inventory on a weekly base.

All our machines are available on our premises, ready to be tested and shipped to you!