0 items in quote

Worldwide export

Premium tested machines

Readily available

Trade in possible

2800+ machines in stock

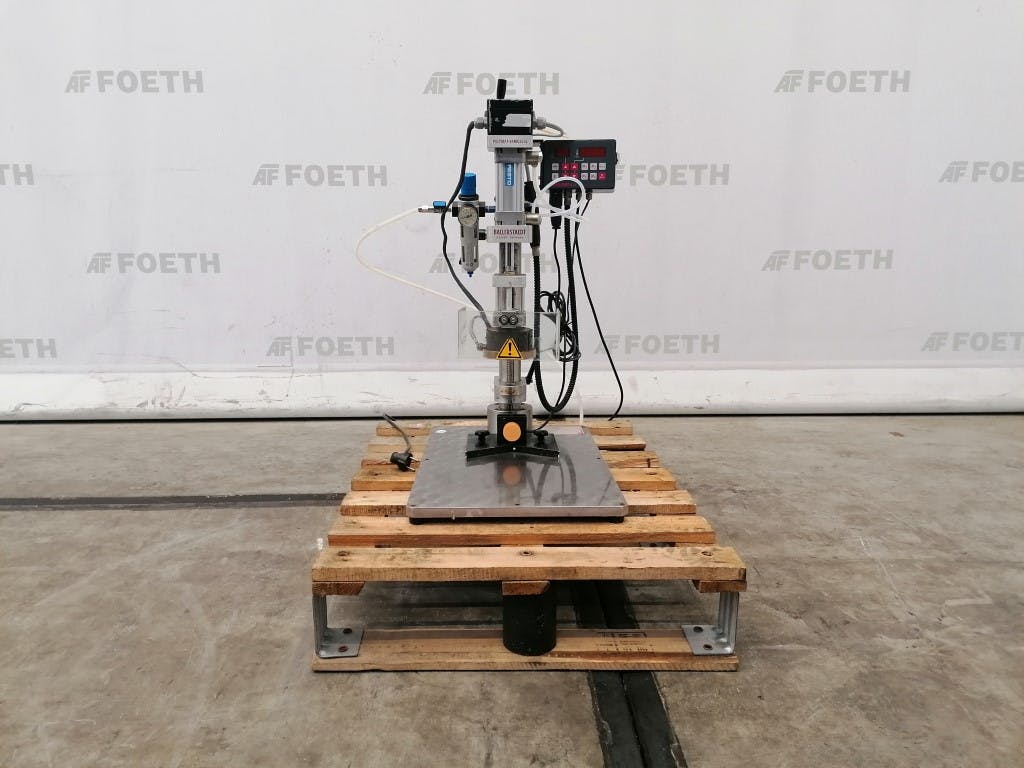

If you're looking for an inexpensive, operational capper, you've come to the right place! These used capping machines are indispensable to many modern, efficient production lines. You'll find several models from well-known brands, such as Bausch & Ströbel, Pohl & Co, and Albertina Machinery, all tested by our technical experts and immediately available to be shipped!

Find your cost-efficiency in our inventory!

We only have machines from premium European manufacturers and mechanically test prior to shipment

Foeth has the largest stock in Europe and we update our inventory on a weekly base.

All our machines are available on our premises, ready to be tested and shipped to you!