0 elementos en la cotización

Temas

Industria

Categoría

Especificaciones PDF

Solicitar cotización

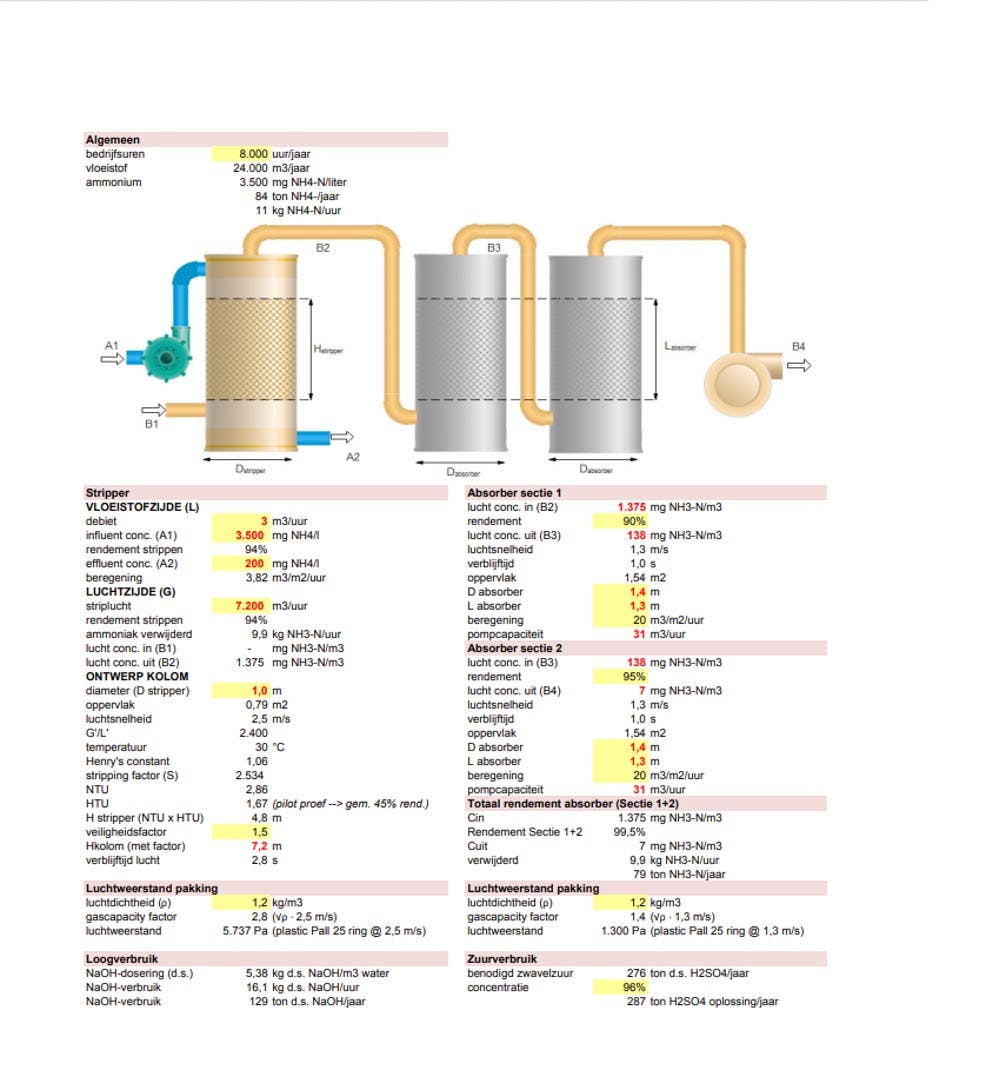

Altop Ammonium Stripper

-Lavadora de gases

- General

- SKULU001

- UbicaciónPaíses Bajos

- HacerALTOP kunststoftechniek

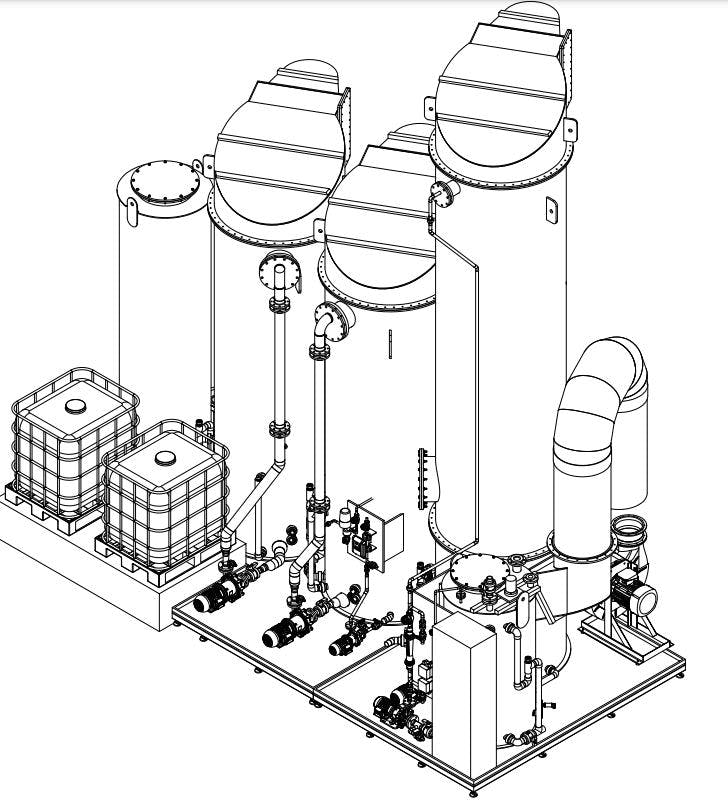

- TipoScrubber Stripper combi skid

- Año de construcción2017

- Principales características

- Capacidad3000 Ltr./Hr.

- Características especificados - Lavadora de gases

- CapacidadStripper liquid: 3,0 m3/h, Air flow: 7200 m3/h, Ammonium 9,9 kg NH3-N/h

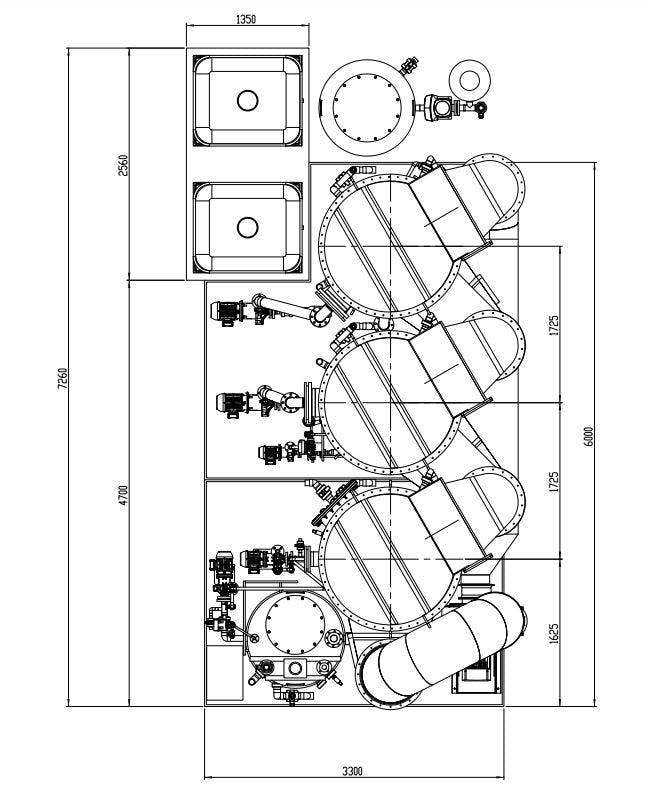

- Tamaños del recipienteStripper Dia: 1000 mm

- Número de columnas:1c stripper, 2pc scrubbers

- Con agitadorflux mixer

- Con bomba

- Información

- Con aparamenta

- Altura total8,0 m

- CE

- Espacio de piso6,0 x 3,3 m

- Especificaciones adicionales

Información adicionales

The system consists of the following main components:

- Scrubber 1

- Scrubber 2

- stripper vessel

- Process water supply by means of valve ABV403

- Acid dosing by pump PU501

- Ammonium sulphate removal by pump PU303

Objective: neutralise ammonia vapour generated in the stripper. Sulphuric acid dosing will convert ammonia into ammonium sulphate. The ammonium sulphate will be pumped to an external storage tank by means of pump PU303. The acidity in the scrubber will be controlled by a pH measurement. Ammonium sulphate pumping is controlled by level measurement LT301, pH measurement and/or conductivity measurement QT301. Both scrubbers are operated continuously. Circulation pumps PU301 and PU302 are thus operated continuously with the exception of various safety devices. The air is circulated by means of fan FAN201. The starting point is clean air on the suction side of the fan ( i.e. washer stage 2, scrubber 2 ). The air is blown through the stripper. A reaction takes place in the stripper where ammonia is released. The contaminated air is led to scrubber 1, where most of the ammonia is removed. Next, the air is led to scrubber 2. This stage has to remove any residual ammonia in the air. After scrubber 2 ( wash stage 2 ), the starting point is again clean air blown through the stripper. Cycle repeat again. So this too is a continuous process.

- Scrubber 1

- Scrubber 2

- stripper vessel

- Process water supply by means of valve ABV403

- Acid dosing by pump PU501

- Ammonium sulphate removal by pump PU303

Objective: neutralise ammonia vapour generated in the stripper. Sulphuric acid dosing will convert ammonia into ammonium sulphate. The ammonium sulphate will be pumped to an external storage tank by means of pump PU303. The acidity in the scrubber will be controlled by a pH measurement. Ammonium sulphate pumping is controlled by level measurement LT301, pH measurement and/or conductivity measurement QT301. Both scrubbers are operated continuously. Circulation pumps PU301 and PU302 are thus operated continuously with the exception of various safety devices. The air is circulated by means of fan FAN201. The starting point is clean air on the suction side of the fan ( i.e. washer stage 2, scrubber 2 ). The air is blown through the stripper. A reaction takes place in the stripper where ammonia is released. The contaminated air is led to scrubber 1, where most of the ammonia is removed. Next, the air is led to scrubber 2. This stage has to remove any residual ammonia in the air. After scrubber 2 ( wash stage 2 ), the starting point is again clean air blown through the stripper. Cycle repeat again. So this too is a continuous process.

Descargar especificación

Get machine specifications in a shareable and printable PDF¿Interesado?

Let’s reuse to reduce

Solicitar cotización