0 items in quote

.JPG%3Fv%3D3&w=3840&q=75)

Worldwide export

Premium tested machines

Readily available

Trade in possible

2800+ machines in stock

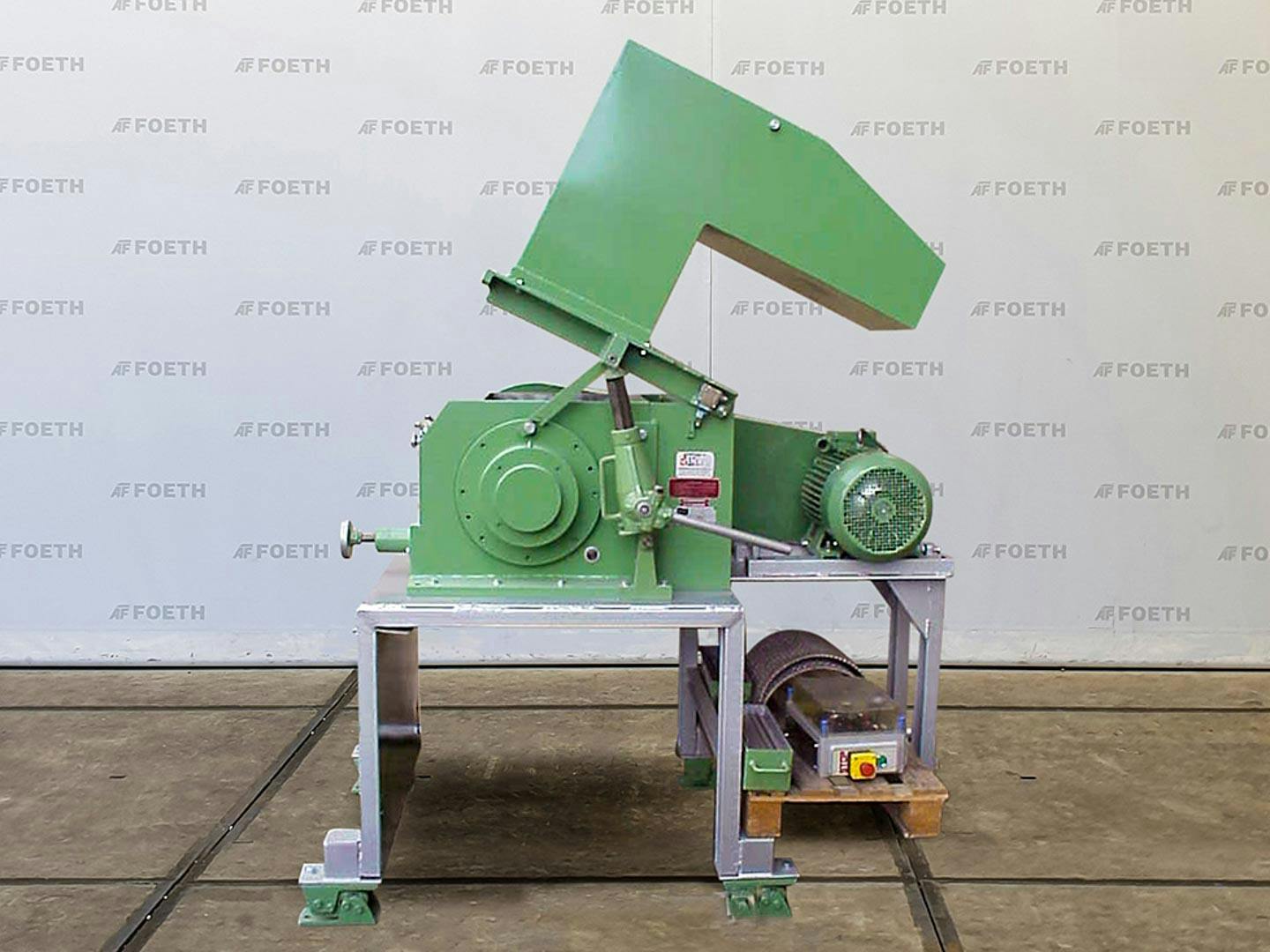

At Foeth we have a wide range of used granulator mills available from leading brands such as Pallmann, Tria, Rapid, and others. All our equipment is tested and approved before sale. We invite you to visit our facilities in Barneveld, The Netherlands, to see the types of granulators available and the particle sizes they can achieve. You can also contact us via our website. We prepare quotations without obligation and we export worldwide. Read more about granluators

Discover the types of used granulators available at Foeth!

.JPG%3Fv%3D3&w=3840&q=75)

.JPG%3Fv%3D3&w=3840&q=75)

.jpg%3Fv%3D3&w=3840&q=75)

We only have machines from premium European manufacturers and mechanically test prior to shipment

Foeth has the largest stock in Europe and we update our inventory on a weekly base.

All our machines are available on our premises, ready to be tested and shipped to you!

Granulation is one of the most important unit operations in the preparation of oral pharmaceutical formulations. Granulation agglomerates fine particles, creating bonds between them, which are formed by compression, drying, or by using a binding agent.

The term is also applied to the granulation of solids, a process in which the raw feed material is crushed or cut into finer granules. This operation is basic as a reprocessing technique in plastics purging or waste recycling. These processes are carried out using a granulator.

Depending on the type of technology, the equipment can be classified as follows:

Rotary granulators or knife mills: these are used in particle size reduction, employing a guillotine rotor. With this, further processing or fine grinding of the material is facilitated. This also allows the product to be transported, mixed or stored.

Centrifugal granulators are ideal for wet granulation processes. Using centrifugal force, the powders are mixed with a high-speed impeller. The mixture is wetted by spraying a binding liquid, resulting in the formation of granules. An internal cutter reduces the size of the large agglomerates formed during the process. Widely used as a pharmaceutical granulator

Oscillating granulators are used in dry granulation processes. The granules are formed by compaction, using a roller, and fed by an auger. The compacted product is ground or cut, to the required granule size.

In addition to the pharmaceutical industry, granulators are used in the production of animal feeds, fertilisers, flavours, cosmetics, dyes and pigments. They are also used to convert wood, or straw, into biofuels in granular form.

In the recycling industry, knife granulators facilitate the processing of waste material prior to reuse. Pallmann PS granulators are ideal for different types of rubber or plastic and can cut into granules smaller than 10 mm.

Plastic rejects from injection moulding and blow moulding processes are also processed before reprocessing. This is one of the features of the Rapid or Tria granulators, which are available in our inventory.

If you require additional information on industrial granulator mills or require a specific application, please call our technical sales agents or contact us via the Foeth contact form.

Buy a used granulator for your process from Foeth today!

If we do not have your desired process equipment in stock, please let us know! Our purchase team will try to find the best matching machine for you via their international purchase network.