0 items in quote

.jpg%3Fv%3D3&w=3840&q=75)

Worldwide export

Premium tested machines

Readily available

Trade in possible

2800+ machines in stock

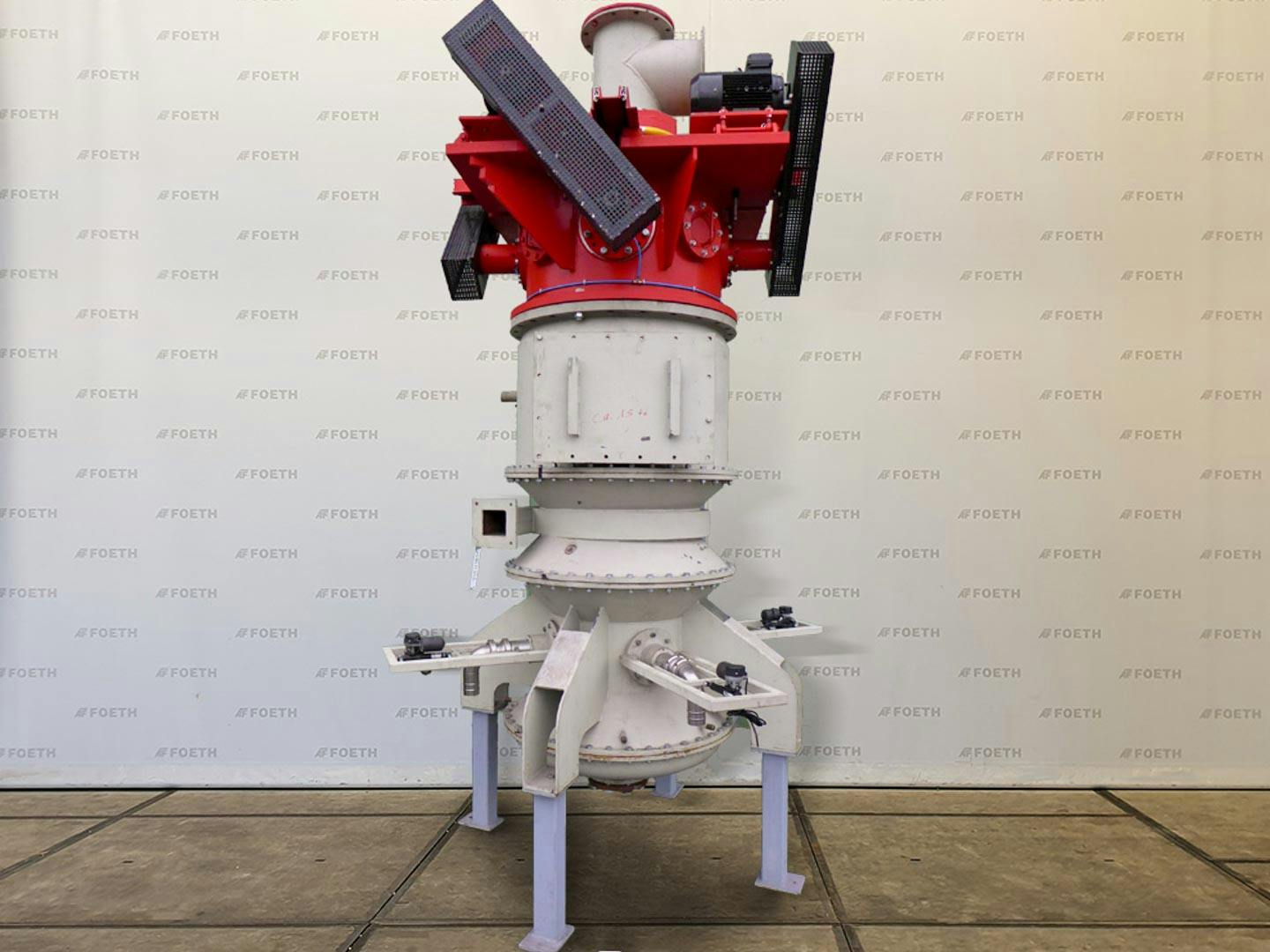

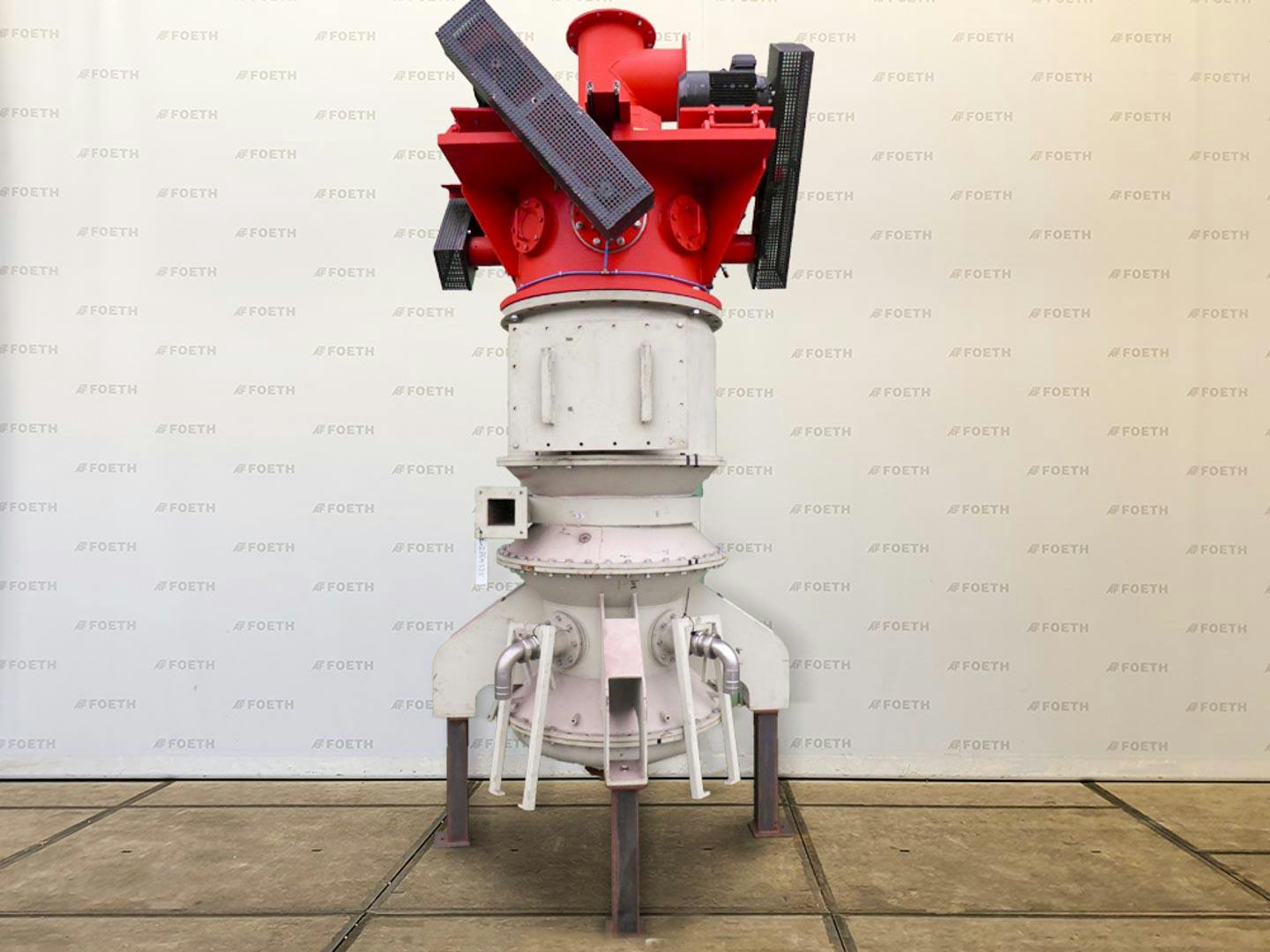

If you are looking for a classifier mill, Foeth has got you covered with the best quality machines. The mills can grind and classify items to simplify your production process. For instance, a classifier is useful for ultra-fine grinding, depending on the nature of the product. The mills produce uniform particle sizes and are suitable for processes that require temperature control due to the sensitivity of the ingredients to heat. The classifying action improves the quality and physical properties of the product. Foeth has classifiers from various brands, and you can buy new or used machines that fit your budget. The used machines perform as efficiently as new ones since they are mechanically tested to ensure they perform optimally.

Get a suitable classifier mill for your industrial processes.

.jpg%3Fv%3D3&w=3840&q=75)

a.jpg%3Fv%3D3&w=3840&q=75)

.jpg%3Fv%3D3&w=3840&q=75)

.jpg%3Fv%3D3&w=3840&q=75)

.jpg%3Fv%3D3&w=3840&q=75)

-bewerkt%20kopi%C3%ABren.jpg%3Fv%3D3&w=3840&q=75)

We only have machines from premium European manufacturers and mechanically test prior to shipment

Foeth has the largest stock in Europe and we update our inventory on a weekly base.

All our machines are available on our premises, ready to be tested and shipped to you!

A classifier mill has a grinding and milling system for breaking down particles of various materials. A particle size classifier continuously recirculates particles back to the grinding zone to ensure that the granules are a similar size. Many classifiers are available on the market, and you can choose the ideal mill for your needs based on the desired particle size, industrial application and the physical properties of the materials. For instance, you can find classifiers for recovered carbon black, which is recycled back to the tyre production chain. Recovered carbon black usually provides a challenge in refining the pyrolysed tyre materials to be used in manufacturing rubber products. A classifier helps achieve consistent fineness through efficient milling, grinding and classifying. An air classifier mill is ideal for processing various products that require fine and ultrafine grinding of medium-hard products. The common applications of air classifiers are producing powder coatings, pharmaceuticals, food and minerals. They are perfect for combined drying and grinding.

A classifier mill works by injecting a stream of material into a chamber using airflow. Inside the separation chamber, the materials are separated depending on their size and shape. Classifiers are often employed in industrial processes that require separating large volumes of mixed materials with different physical characteristics. The common application is in cement and mineral classification. You can also use classifiers in food processing and pharmaceutical industries for producing products like milk powder and medicine in powder form. Aside from chemical and cosmetic production, classifiers are also useful for air pollution control and in municipal recycling centres that separate various types of paper, metal and plastics. Such classifiers use electromagnets to separate metals and grinders to refine plastics into reusable particles.

Order a new or used classifier mill from Foeth today.

If we do not have your desired process equipment in stock, please let us know! Our purchase team will try to find the best matching machine for you via their international purchase network.