0 items in quote

.JPG%3Fv%3D3&w=3840&q=75)

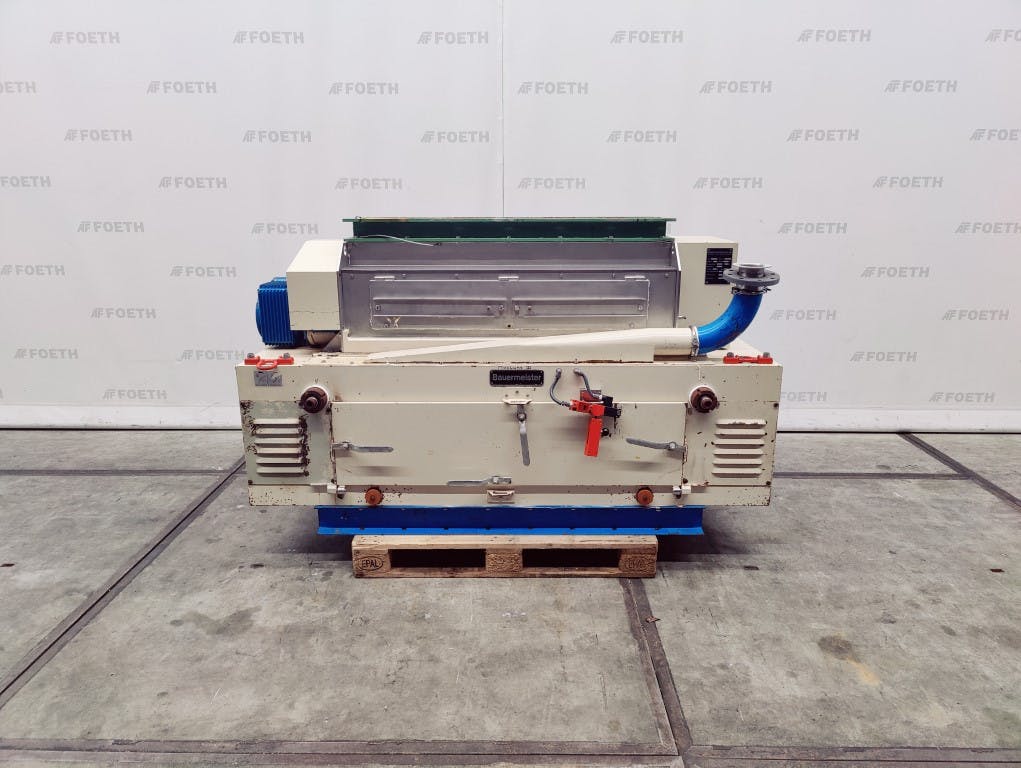

Worldwide export

Premium tested machines

Readily available

Trade in possible

2800+ machines in stock

.JPG%3Fv%3D3&w=3840&q=75)

.jpg%3Fv%3D3&w=3840&q=75)

We only have machines from premium European manufacturers and mechanically test prior to shipment

Foeth has the largest stock in Europe and we update our inventory on a weekly base.

All our machines are available on our premises, ready to be tested and shipped to you!